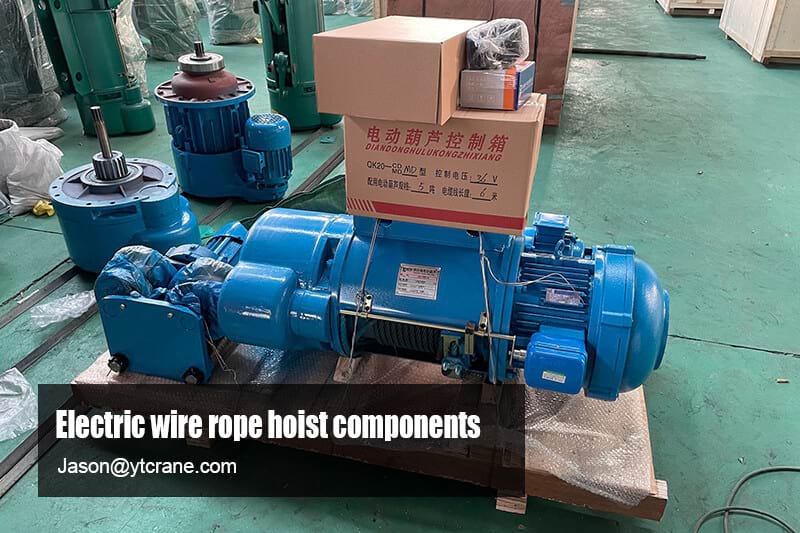

The electric wire rope hoist is composed of a conical rotor motor, a reducer, a reel device, a coupling, a rope guide, a hook device, an electric trolley, a drive device, and electrical appliances. Each component can be relatively independent in structure, and it is convenient to maintain and adjust.

Three-phase AC conical rotor motors are the lifting motive force of many wire rope electric wire rope hoists. This series of motors are intermittent rated working methods, with a load duration rate of 25% and an equivalent number of starts per hour of 120.

The structure of the conical rotor motor has the characteristic of generating axial magnetic pulling force. The brake friction plate is installed on the fan brake wheel, and the lock nut and screw fasten the fan brake wheel to the rear end of the motor rotor shaft. When starting, the magnetic pulling force overcomes the spring pressure, so that the fan brake wheel integrated with the rotor and the rotor produces axial displacement, the brake ring is separated from the rear cover, and the rotor rotates freely. After the power is off, the magnetic pulling force disappears. Under the action of the pressure spring, the fan brake wheel and the end cover are braked tightly, and the braking effect is obtained by relying on the friction force generated by the conical surface. When braking under the rated compliance, the sliding distance of the heavy object should not exceed 1/100 of the lifting speed, otherwise, it should be adjusted. When adjusting, loosen the screw and tighten the lock nut to increase the pressure of the spring and obtain a larger braking torque.

The reducer adopts a cylindrical helical gear three-stage reduction, the driving device adopts a cylindrical spur gear two-stage reduction, and the gears and gear shafts are made of alloy structural steel and have undergone heat treatment. The shell is made of cast iron, tightly assembled, and dust is not easy to invade.

Reels of 0.5 ton, 1 ton, 2 ton, 3 ton, and 5 ton are made of cast iron when the lifting height is 6 to 12 meters; when the lifting height is greater than 12 meters, they are made of seamless steel pipe. One end of the reel is connected to the reducer through a spline, and the other end is mounted on the bearing position protruding from the end cover of the main motor through the bearing of the reel. The wire rope is wound in the rope groove of the drum, and the rope end is fastened to the drum with a rope pressing plate. When replacing the wire rope, only need to start the motor so that the bolts of the rope pressing plate can be removed from the gap in the shell of the drum.

The hook device of 0.5 ton, 1 ton, 2 ton, 3 ton and 5 ton is a single pulley type; the hook device of 10-20 tons is a double pulley type. The pulley is made of cast iron; the hook is forged from high-quality carbon structural steel, suspended on the single thrust ball bearing in the beam, and connected to the pulley through the beam and the hook shell.

The rope guide is composed of a rope guide nut, a rope guide plate, and a connecting steel belt. The guide rope nut is cut into 5 pieces, which are connected by the connecting steel belt and the guide rope plate into a whole. The wire rope protrudes from the long groove of the rope guide plate. The guide rope nut engages with the rope groove of the reel, and the rotation of the reel drives the guide rope nut to move laterally, so as to ensure that the steel wire rope is not buckled in the rope groove of the reel.

The rope guide plate moves laterally to both ends of the drum. When the limit position is reached, the limit rods installed on the drum shell move together, and when the limit position is reached, the limit switch installed on the main motor is activated to limit the position.

The electric trolleys of 0.5 ton, 1 ton, 2 ton, 3 ton and 5 ton are equipped with 4 walking wheels when the lifting height is 6 meters and 9 meters (including 0.5 tons and 12 meters). When the lifting height is equal to or greater than 12 For meters, a small frame board with two walking wheels is added. At this time, two joint bearings are added to the joint between the electric trolley and the drum shell. The electric wire rope hoist of 10-20 tons is connected with the drum shell by 2 electric trolleys and 2 joint bearings. In order to adapt to different types of I-beams, adjusting washers are installed at both ends of the bolts.

The torque of the main motor of the electric wire rope hoist is transmitted to the reducer through the elastic coupling. The coupling can absorb the impact load and obtain a balanced start.

The operation of the electric wire rope hoist is realized by the suspension button switch and the electric wire rope hoist control box installed on the side of the electric trolley. The hoist adopts the soft cable lead-in, through the soft cable lead-in device, the electric current is introduced into the electrical control box, and the installation is convenient.

Get Free Quotation