Things to make sure before installation of Electric Chain Hoists:

The Electric Chain Hoists and Electric trolleys are packaged respectively. Firstly check if the quantity of the hoist accords with the number of units in invoice and if there are any damages occurred from the transportation of abnormal packing. Also, Check the nameplate and see if the rated capacity, lifting speed, lifting height, cross travelling speed as well as the power supply is up to standard. Check if screws of top hook set are loosed and if the chains are knotted and twisted.

Check the track where the hoist and trolley combo is to be mounted

The run track of the hoist adopted is the I- Beam steel. The range of width is 75-180 mm for 1T – 2T and 100-180 mm for 3T-5T. The track for running should be smooth and its swerve radius cannot less than the minimum radius stipulated in the nameplate. The placement of axle height at the end of track should be fixed an elasticity buffer to guarantee the safe running of a trolley.

Assemble the hoist and trolley

When assembling, the number of adjustment washers for right and left between the flying ring and both sides’ plates should be equal. More one thin piece of adjustment washer shall be allowed in order to ensure the clearance of 3 mm between the flank and flange of the track. For the max or minimum width of the track, there should be one piece of washer at least.

Installation for the whole hoist

Tighten the nuts inboard of the beam after the hoist is fixed on the track. And have a test run with a light load. Tighten the nuts outboard of the beam after the wheel contacts the track completely. Pay attention especially that the nuts inboard of the beam must interlock the nuts outboard.

The clearance between the roller and the bottom of the track should be adjusted to 4mm.

The way of adjustment is loose the nuts of the roller and move the roller, tighten the nuts after the clearance is up to standard.

Installing trolley and connecting it to the hoist

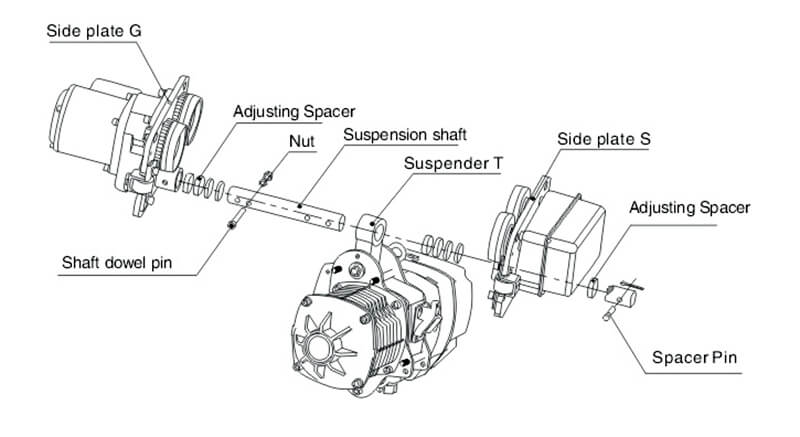

(a) Equipping trolley

- Insert suspension shaft into side plate G and lock it with suspension shaft bolt, slotted nut and split pin. Ensure to fully bend both branches of split pin.

- Insert fixing shaft into side plate and lock it with a split pin. Ensure to bend both branches of split pin.

- As shown in table 5-2, load the suspension shaft with inner adjusting spacer.

- Attach suspension shaft and fixing shaft to suspender T connecting with hoist body. Make sure that mane plates of hoist and trolley are in the same direction.

- Attach more spacers on suspension shaft, and insert the suspension shaft and fixing shaft into side plate S.

- Attach outer adjusting spacer and shaft stopper pin on the suspension shaft. Insert the split pin into the shaft stopper pin.

- Install shaft stopper and you can see the split pin on the left side from the front of trolley switch box when.

(b) Adjusting trolley width

- Adjust trolley width for proper space by referring to the above picture. Size A is measured when two side plates are fully extended out.

- Size A must be: about rail flange width (B) + 41n1n

- To obtain above-stated size A, you should increase or decrease adjusting spacers, without taking into consideration the numbers listed in Table 5-2.

- After size A is measured, insert a split pin into shaft stopper pin. Ensure to bend the two branches of split pin.

After reading this article, you may have a certain understanding of the installation of electric chain hoist. So, what problems have you encountered during the installation of the electric chain hoist? Welcome to leave a message and discuss.

Get Free Quotation