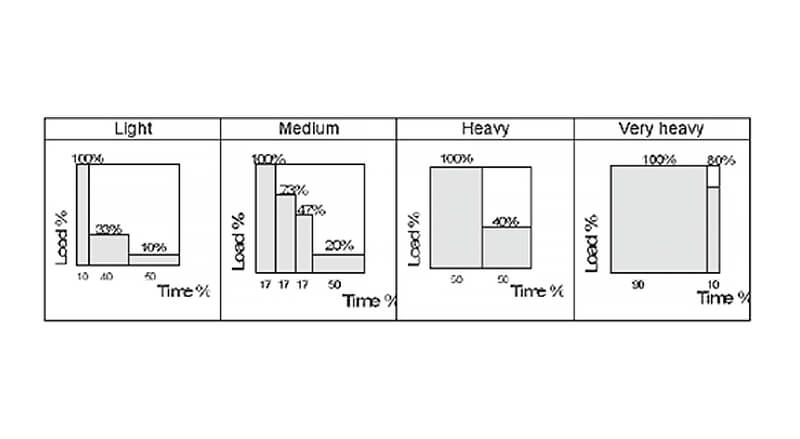

The safe operation period of the lifting mechanism depends on whether it is used correctly according to the specific working level. According to the European Handling Association standard FEM9.511 and the relevant Chinese national standards, the working level of the hoisting mechanism of the crane is determined by the load spectrum and the average daily operating equivalent time.

Load Spectrum

|

Light |

Medium |

Heavy |

Very Heavy |

|

Occasional full load |

Occasional full load |

Repetitive full load |

Usually almost full load |

Average daily operating time

The average daily equivalent use time can be calculated according to the actual use time according to the statistical method. The reference formula is as follows:

t=(2 x N x H x T)/(V x 60)

H = average hoisting height (m)

N = number of work cycles per hour (cycles/h)

T = daily working time (h)

Determining the working level of the hoist

When the load spectrum and the average daily equivalent use time are determined, the work level can be found according to the data in the following table:

| Load Spectrum | Average daily operating time ISO(GB) / FEM (hours per day) | |||||

| ≤0.5 | ≤1 | ≤2 | ≤4 | ≤8 | ≤16 | |

| Light | M3 1Bm |

M4 1Am |

M5 2m |

M6 3m |

||

| Medium | M3 1Bm |

M4 1Am |

M5 2m |

M6 3m |

M7 4m |

|

| Heavy | M3 1Bm |

M4 1Am |

M5 2m |

M6 3m |

M7 4m |

|

| Very Heavy | M4 1Am |

M5 2m |

M6 3m |

M7 4m |

||

Example: The crane load spectrum of a user is Medium, the lifting speed V=5m/min, the average working height H=3m, the average working cycle N=5 times per hour, and the two-shift daily working time T=16 hours. We can calculate the equivalent working time is t=1.6, and the working level found from the above table is Chinese national standard M5 (equivalent to the European standard 2m).

Get Free Quotation