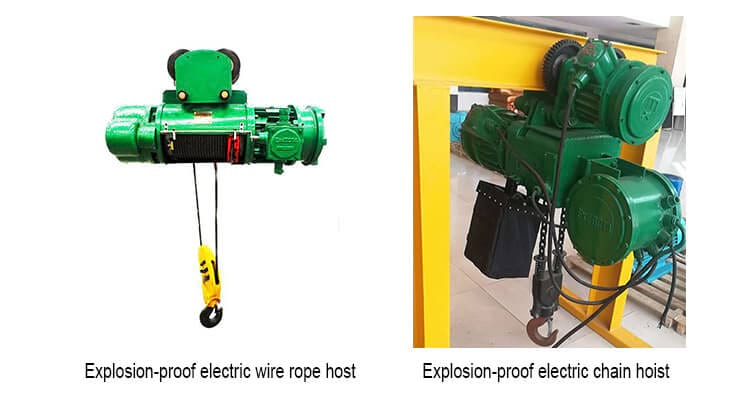

Explosion-proof hoist, as the name implies, is a kind of hoist that can be used in explosion-proof places. According to different types of work, it can be divided into two types: explosion-proof chain hoist and explosion-proof electric hoist. The following editor mainly introduces the latter, which is mainly installed on a fixed bracket for lifting heavy objects. Because it is used in some places with combustible gas and volatile gas, the design is different from the general electric hoist. According to the specific characteristics, the factors considered in the design are also different. See below for details.

The characteristics of explosion-proof electric hoist

The chain or wire rope of the explosion-proof hoist is generally treated with special treatment, so there will be no sparks during friction, and other parts are also tested for explosion-proof, so there is another measure for the safety of use. Generally speaking, its materials are relatively strong and cost-effective. It has the characteristics of ordinary electric hoists. For example, it is used for lifting goods when carrying goods and repairing equipment. It can be used even if the equipment is damaged and leaks flammable gas. In the mining, chemical, pharmaceutical and other industries.

The elements to be considered in the design of explosion-proof electric hoist

The main feature of the explosion-proof hoist is the explosion-proof function, so in the design, the pressure and explosion-proof performance should be considered, so that it can be used in the range of flammable or volatile gases such as ethylene, coal gas, gasoline, and ethane. Therefore, when designing the electrical machinery part, the explosion-proof structure should be adopted. The electrical machinery part includes motors, electromagnets, power transmission cables, etc. In addition, switches that often carry arc lights should be designed; the brake part cannot use the explosion-proof structure. However, the brake contains heat-generating parts, so the temperature rise needs to be clarified when designing.

In order to facilitate maintenance and repair, junction boxes are required at the power supply part, the two ends of the button cable, the motor, the electromagnetic brake, and the electromagnet box.

In order to improve safety, the junction box can also adopt a pressure-resistant and explosion-proof structure, and the junction box and power switch can be designed outside the electric hoist. The power supply is reliably grounded. The operator operates on the ground, and other accessories constitute the whole, install it on the overhead track and move it.

Get Free Quotation