This is an overhead bridge crane case between Bolivian client and us. Jose, a Bolivia customer, communicated with us online about his overhead crane needs and left detailed contact information.

Customers need fast and efficient communication. Compared with traditional email communication, the communication of instant messaging software such as WeChat and WhatsApp are very efficient. Therefore, we created a WeChat group to discuss the detailed requirements of this project with his engineer Eric.

Basic overhead crane demands of Jose

- Crane type: overhead crane

- Capacity: 5 ton

- Width: 29.5 meters

- Height: 6 meters

- Power supply: 380V 50Hz 3 Phase

- Application: lift some plastic pipes, 12m long and 1 ton of weight

Jose is not sure whether single-girder or double-girder cranes are more suitable for him, but he has a request, "Which one is the cheapest?". Under the same parameters and working conditions, the price of the single girder overhead crane is much cheaper than that of the double girder bridge crane. Since the customer's working condition is also a general-purpose working condition, we recommend single girder overhead crane to the him which is more advantage.

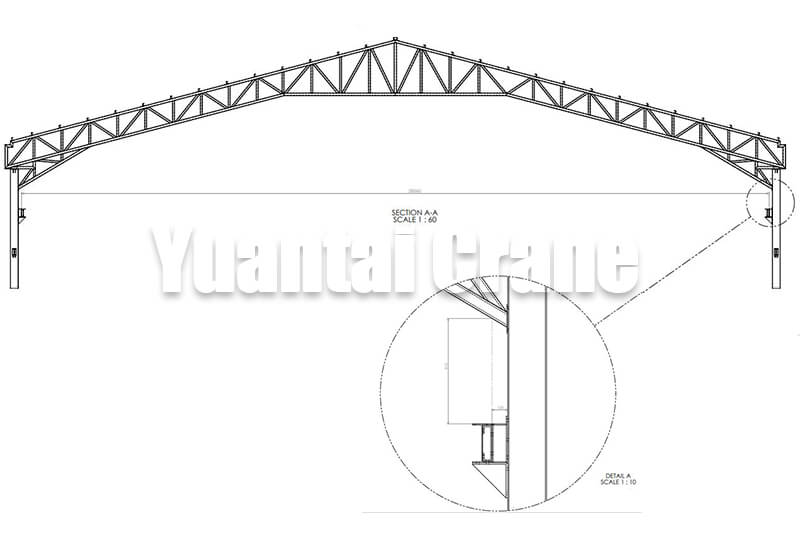

The initial communication was very smooth. Eric sent us the factory building drawings they designed and marked the specific size of the bridge crane to be placed. It was very intuitive. We only need to design the crane to match their requirements.

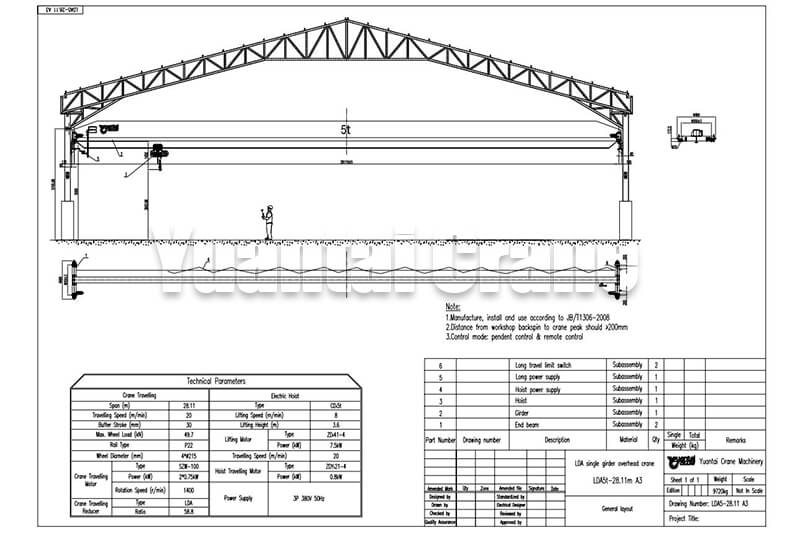

It can be seen from the drawings that the span of the bridge crane is 28.356m. Since the height of the customer's factory building is only 6m, the lifting height that can be achieved is only about 3.6m after removing the headroom height of the crane. According to these parameters, we designed a single girder overhead crane solution for the customer and provided a quotation for the solution.

Bolivia 5 ton overhead crane drawing

Bolivia 5 ton overhead crane quotation

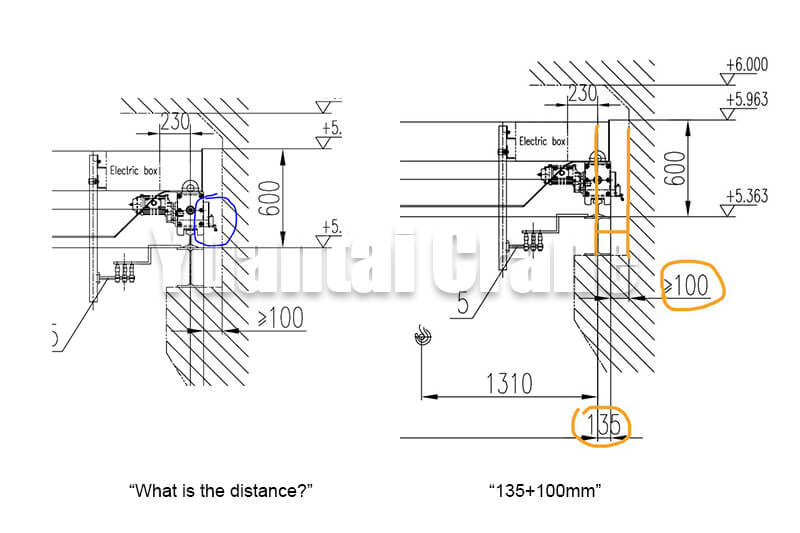

After reviewing the drawings of the bridge crane, the engineer Eric pointed out that the drawings of the factory building they designed had horizontal restrictions. The bridge crane we designed had a certain distance between the rail and the wall. It may be that they have not touched the design of the bridge crane before. All bridge cranes must leave an appropriate distance between the rail and the wall to ensure that the end beam can be installed and operated normally.

Bolivia customer's question

Eric asked about the distance from the center of the rail to the wall, the distance had actually been clearly marked in our design drawing. The distance from the center of the rail to the wall should be at least 135+100mm.

Based on our suggestion, Eric modified their plant design by moving the corbels down and increasing the distance from the bearing beam to the wall. Therefore, the span and lifting height of the overhead crane will change accordingly.

Bolivia factory building drawing modification

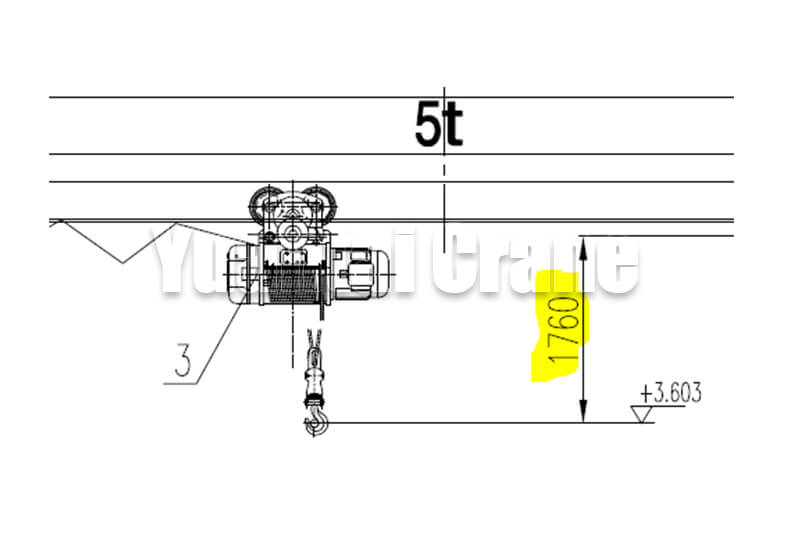

At the same time, Eric raised a question, "is there any chance to have a minor measurement for this?". He wants to reduce the headroom of the hoist. Of course, it is possible to replace the current hoist with a low-headroom hoist to increase the headroom.

Headroom of electric hoist

According to the customer's modification, we redesigned the single girder overhead crane, and merged the drawings with the customer's workshop drawings, which looks more intuitive. The customer also requested to design a double girder bridge crane with the same parameters for comparison and selection.

Bolivia 5 ton single girder bridge crane drawing

5 ton single girder overhead crane quotation

5 ton double girder overhead crane drawing

5 ton double girder overhead crane quotation

By comparing the two solutions, the customer decided to purchase the 5 ton single girder overhead crane, which is more cost-effective. The customer confirmed the size information of the final bridge crane with us, and after confirming that it was correct, he placed an order.

This is an international cooperation. The plant builder and the crane supplier perfectly integrate two different products to provide one-stop solutions for end customers.

Get Free Quotation